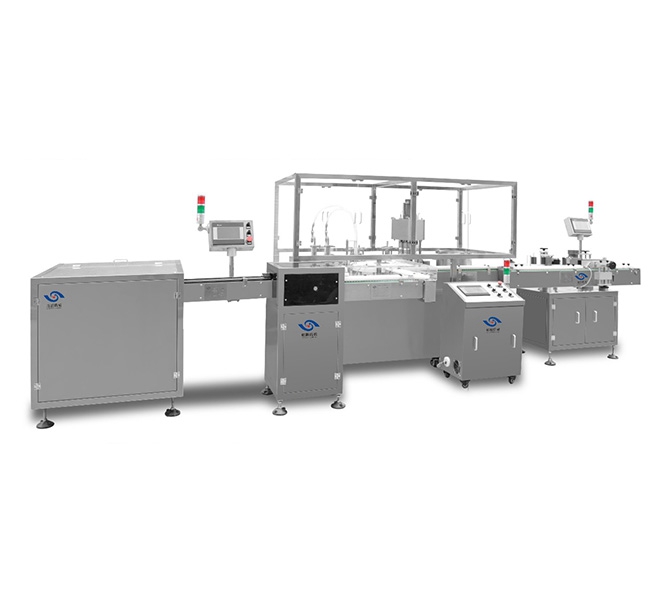

The production line is composed of bottle making machine, filling and capping machine, lamp checking machine, labeling machine and other equipment, and can also be used on a single machine. It is suitable for 2-30ML series products, such as filling, filling, checking, labeling. It can be applied to multi standard products with wide application scope and convenient adjustment.

Equipment Features:

The bottle making machine can be used as a storage box, and can also complete the feeding bottle, and the adjustment is convenient.

The bottle machine adopts the cosine acceleration cam drive mechanism to finish the feeding, and the servo motor completes the bottle, the operation is stable and reliable, and the bottle can not be inverted. It can be used alone and can be used to connect various equipment.

The filling machine adopts the acceleration inlet bottle, and the speed reducing double outlet mechanism ensures the stable entry and exit of the bottle, and does not appear in the bottle or the card bottle.

Servo motor control measurement, easy to adjust.

The upper cover of the manipulator is used to plug the upper cover and the servo motor is used to send the stopper to ensure the stable entry of the stopper and the lid.

The upper part of the upper part of the filling machine is mechanically pressed and exported, and the positioning is accurate, so that the pollution of the equipment can be effectively controlled without the need of gas source and vacuum.

The capping part of the filling machine adopts a constant torque cap, and the cosine acceleration cam transmission mechanism completes the lifting and the mechanical arm is used for pressing the bottle.

The lamp inspector is weighed by intelligent module, and the bottle cap and bottle body are scanned by 3D camera, which can effectively guarantee the pass rate.

The whole line adopts touch screen intelligent control, which is stable and reliable.

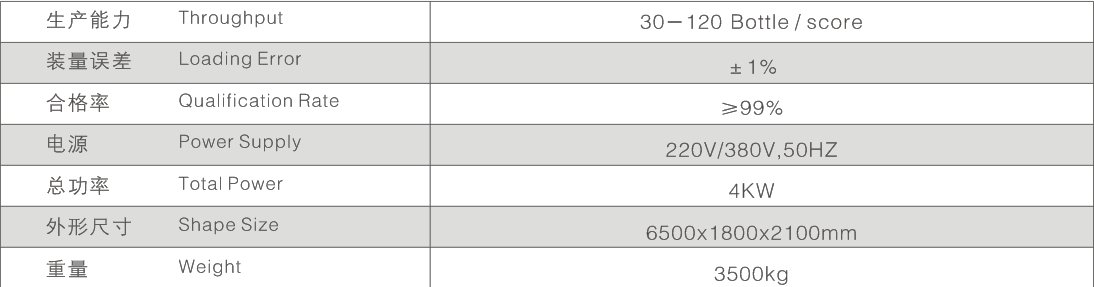

Technical Parameter: