Y-GS filling and filling machine adopts linear filling, precise loading, mechanical plugging, stable performance and no pollution. It is easy to maintain and can make production line with the production equipment before and after.

Equipment Features:

A filling plug machine, which consists of a bottle feeding part, a rack part, a filling part, a plug part, a plug part, a bottle part, a metering pump component and an electronic control component, which is characterized by a disc structure with a bottle body guided by a bottle with a container body at the end of the screw. The outlet of the trough corresponds to a groove on the dialing wheel on the filling part. It is located at the entrance of the filling part. The metering pump parts are placed on the side of the filling part. The plug components are located at the exit of the filling parts. At the same time, the parts are connected with the plug components and the outlet is connected with the bottle. The structure of the utility model is compact and simple, and the number of connection of the bottle body is few, and the disc bottle transmission method can avoid the phenomenon of breaking the bottle and the bottle deficiency, and the equipment performance is improved. At the same time, the plug part adopts the integral disc vacuum adsorption glue plug method, and the bottle body is lifted to complete the pressing process by the spiral plane of the lifting cam, and the whole process is completed. Continuous, high production efficiency, convenient maintenance.

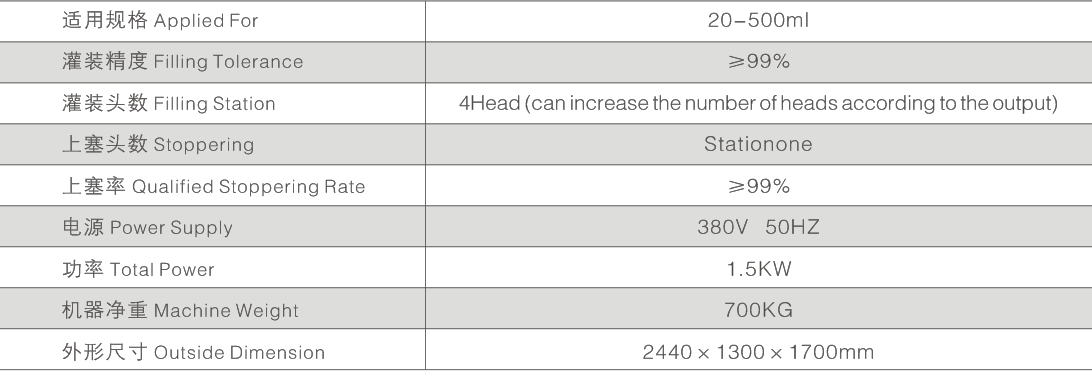

Technical Parameter: