rief introduction to the use of Xilin bottle filling and stopping machine:

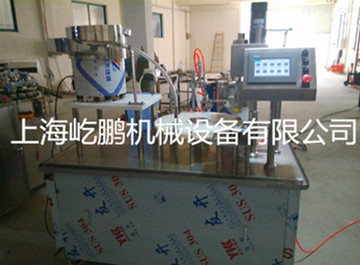

YGZ Series Xilin Bottle Filling Machine is an ideal equipment for filling and stopping high-yield water needle and lyophilized preparations.

Ceramic mercury can be selected for filling machine.

Bottle-free and stoppage-free filling

Compliance with GMP Quality Specification

The filling machine adopts the mode of transporting bottles with horizontal synchronous belt, which has high speed, accurate bottle division and convenient replacement of specifications.

PLC Program Control, Touch Screen Function Display and Operation

Stainless steel mercury and creeping mercury

Silin bottle filling stopper can be equipped with servo filling form (Delta, Mitsubishi, Rockwell, Siemens)

The filling part of filling machine adopts horizontal feeding plug and horizontal disc suction plug, which has the characteristics of convenient observation, convenient feeding and high feeding speed.

Technical parameters for use of filling stopper for Xilin bottle

Power supply 380V 50Hz

Applicable Specifications 2-20ml

Total power gross power 2 kW

Measurement error measuring error 1 m meter

Breaking rate < 0.1%

Qualified rate of cork-putting (> 98%)

Vacuum Mercury Pumping Rate of Vacuum Pump 20/h

Gross weight is about 800 kg approximate 800 kg

Production capacity Yield capacity 300 bottles/min bottle/min

Overall size 3500 * 900 * 1700mm

YGZ Series Xilin Bottle Filling Machine is an ideal equipment for filling and stopping high-yield water needle and lyophilized preparations.

Ceramic mercury can be selected for filling machine.

Bottle-free and stoppage-free filling

Compliance with GMP Quality Specification

The filling machine adopts the mode of transporting bottles with horizontal synchronous belt, which has high speed, accurate bottle division and convenient replacement of specifications.

PLC Program Control, Touch Screen Function Display and Operation

Stainless steel mercury and creeping mercury

Silin bottle filling stopper can be equipped with servo filling form (Delta, Mitsubishi, Rockwell, Siemens)

The filling part of filling machine adopts horizontal feeding plug and horizontal disc suction plug, which has the characteristics of convenient observation, convenient feeding and high feeding speed.

Technical parameters for use of filling stopper for Xilin bottle

Power supply 380V 50Hz

Applicable Specifications 2-20ml

Total power gross power 2 kW

Measurement error measuring error 1 m meter

Breaking rate < 0.1%

Qualified rate of cork-putting (> 98%)

Vacuum Mercury Pumping Rate of Vacuum Pump 20/h

Gross weight is about 800 kg approximate 800 kg

Production capacity Yield capacity 300 bottles/min bottle/min

Overall size 3500 * 900 * 1700mm