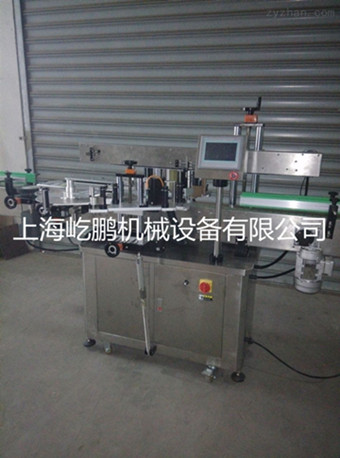

Brief introduction of double-sided labeling machine

Usage: It can automatically attach sticker label and film on product side plane, side large radian surface and square circumference.

Function: Improve the efficiency of product labeling and film sticking, accurate attachment location, good quality and high stability, avoid manual labeling and sticking.

Membrane inefficiency, adherence skew, foaming and folding, irregular attachment location and a series of problems; effectively reduce product costs, improve products

Identify beauty, enhance product competitiveness.

Scope of application: Applicable labels: self-adhesive labels, self-adhesive films, electronic regulatory codes, bar codes, etc.

Applicable products: products requiring labels on side planes, large radian planes, circumferences and square circumferences;

Application industry: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastics, printing and other industries;

Application examples: such as shampoo flask labeling, lubricant flask labeling, shampoo flask labeling.

Working Principle of Double-sided Labeling Machine

Core working principle: the sensor detects the product, sends back the signal to the labeling control system, controls the motor to send out the label and attach it to the position of the product to be labeled in the appropriate position control system, the product flows through the labeling device, the label is attached to the product, and the affixing action of a label is completed;

Vertical labeling method is adopted, special positioning and top pressing devices are installed to ensure the stability of the bottle body; the head can be adjusted up and down, front and back, and tilt, which is suitable for labeling any irregular shape parts; special labeling device is installed to ensure that the label fits smoothly; rotary encoder is used to track, and the conveyor belt can be adjusted at will and the labeling speed keeps synchronization with it all the time.

Irregular shape part labeling; special pressure labeling device is installed to ensure that the label fits smoothly; using rotary encoder tracking, the conveyor belt can be adjusted at will and the speed of labeling always keeps synchronization with it.

Using advanced man-machine interface operation, electro-eye detection, PLC control, rotary encoder tracking, frequency converter speed regulation, to achieve real automation. It is suitable for double-sided labeling of symmetrical or asymmetrical flat, square, oval, cylindrical, conical and special-shaped bottles in food, cosmetics, daily necessities and pharmaceutical industries.

technical parameter

Labeling accuracy: +1 mm

Labeling speed: 0-20 m/min

Label Length: 15-150 mm

Tag Height: 20-150 mm

Thickness of workpiece: 25-120 mm (according to customer requirements)

Workpiece height: 50-320 mm (according to customer requirements)

Paper roll inner diameter: 76 mm

Outer diameter of paper roll: 300 mm

Working voltage: 220V 50/60Hz 1500W

Usage: It can automatically attach sticker label and film on product side plane, side large radian surface and square circumference.

Function: Improve the efficiency of product labeling and film sticking, accurate attachment location, good quality and high stability, avoid manual labeling and sticking.

Membrane inefficiency, adherence skew, foaming and folding, irregular attachment location and a series of problems; effectively reduce product costs, improve products

Identify beauty, enhance product competitiveness.

Scope of application: Applicable labels: self-adhesive labels, self-adhesive films, electronic regulatory codes, bar codes, etc.

Applicable products: products requiring labels on side planes, large radian planes, circumferences and square circumferences;

Application industry: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastics, printing and other industries;

Application examples: such as shampoo flask labeling, lubricant flask labeling, shampoo flask labeling.

Working Principle of Double-sided Labeling Machine

Core working principle: the sensor detects the product, sends back the signal to the labeling control system, controls the motor to send out the label and attach it to the position of the product to be labeled in the appropriate position control system, the product flows through the labeling device, the label is attached to the product, and the affixing action of a label is completed;

Vertical labeling method is adopted, special positioning and top pressing devices are installed to ensure the stability of the bottle body; the head can be adjusted up and down, front and back, and tilt, which is suitable for labeling any irregular shape parts; special labeling device is installed to ensure that the label fits smoothly; rotary encoder is used to track, and the conveyor belt can be adjusted at will and the labeling speed keeps synchronization with it all the time.

Irregular shape part labeling; special pressure labeling device is installed to ensure that the label fits smoothly; using rotary encoder tracking, the conveyor belt can be adjusted at will and the speed of labeling always keeps synchronization with it.

Using advanced man-machine interface operation, electro-eye detection, PLC control, rotary encoder tracking, frequency converter speed regulation, to achieve real automation. It is suitable for double-sided labeling of symmetrical or asymmetrical flat, square, oval, cylindrical, conical and special-shaped bottles in food, cosmetics, daily necessities and pharmaceutical industries.

technical parameter

Labeling accuracy: +1 mm

Labeling speed: 0-20 m/min

Label Length: 15-150 mm

Tag Height: 20-150 mm

Thickness of workpiece: 25-120 mm (according to customer requirements)

Workpiece height: 50-320 mm (according to customer requirements)

Paper roll inner diameter: 76 mm

Outer diameter of paper roll: 300 mm

Working voltage: 220V 50/60Hz 1500W