Points for Attention in Installation of Oral Liquid Filler Price

1. After the machine is unpacked, first check whether the random technical data are complete and whether the machine is damaged in transportation, so as to solve the problem in time.

2. Install and adjust the feeding and discharging components according to the outline of this specification.

3. New lubricants are added to each lubricating point.

4. Rotate the machine with a rocking handle to check whether the machine is running in the right direction (counter-clockwise to the motor spindle). The machine must be protected from earthing.

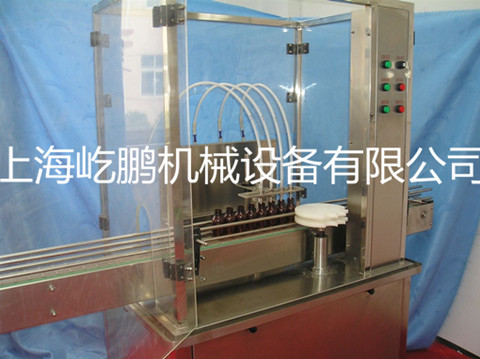

Technical parameters of price for oral liquid filling machine

Yield capacity

40-60 bottles/min (single head) 80-120 bottles/min (double head)

40-60 bottle/min (1 frlling nozzlo)

40-80 bottle/min (2 frlling nozzlo)

Power supply Elctrial supplyity

380V 50HZ

Power Power

1KW

Air supply

10-20_/H 0.3-0.4 kg/c_

Net weight of machine

600kg

Outside dimension

2000mm x 1300mm x 1700mm

Product characteristics

It is suitable for filling and sealing eyedrops in 2-30ml plastic bottles or glass bottles of various types.

The high precision cam indexing mechanism is used to provide indexing to complete the dividing plate, positioning, plugging and upper cover, and the cosine acceleration cam transmission structure is used to complete the lifting of the cap head.

The cap is rotated by a constant torque cap, and the mercury is filled by creeping mercury or ceramic mercury metering.

Touch screen control has the functions of no bottle, no filling, no plug, no plug and no cover.

Precise positioning, smooth transmission, protective cover, accurate measurement, simple operation and so on.

1. After the machine is unpacked, first check whether the random technical data are complete and whether the machine is damaged in transportation, so as to solve the problem in time.

2. Install and adjust the feeding and discharging components according to the outline of this specification.

3. New lubricants are added to each lubricating point.

4. Rotate the machine with a rocking handle to check whether the machine is running in the right direction (counter-clockwise to the motor spindle). The machine must be protected from earthing.

Technical parameters of price for oral liquid filling machine

Yield capacity

40-60 bottles/min (single head) 80-120 bottles/min (double head)

40-60 bottle/min (1 frlling nozzlo)

40-80 bottle/min (2 frlling nozzlo)

Power supply Elctrial supplyity

380V 50HZ

Power Power

1KW

Air supply

10-20_/H 0.3-0.4 kg/c_

Net weight of machine

600kg

Outside dimension

2000mm x 1300mm x 1700mm

Product characteristics

It is suitable for filling and sealing eyedrops in 2-30ml plastic bottles or glass bottles of various types.

The high precision cam indexing mechanism is used to provide indexing to complete the dividing plate, positioning, plugging and upper cover, and the cosine acceleration cam transmission structure is used to complete the lifting of the cap head.

The cap is rotated by a constant torque cap, and the mercury is filled by creeping mercury or ceramic mercury metering.

Touch screen control has the functions of no bottle, no filling, no plug, no plug and no cover.

Precise positioning, smooth transmission, protective cover, accurate measurement, simple operation and so on.