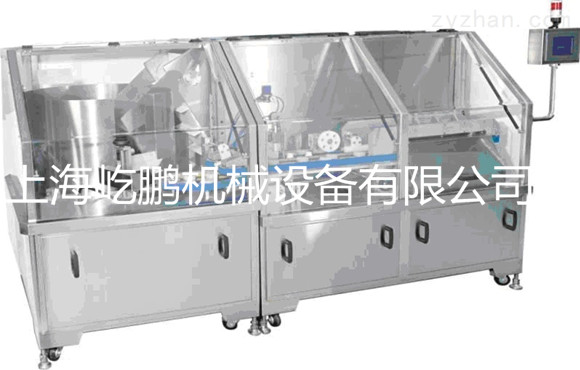

Shanghai Special Bottling Machine Supplier

Working principle:

The function of the special-shaped bottle arranging machine is to store the material manually into the storage bin. The material in the storage bin will be fed to the turntable at an automatic quantitative and set speed. The turntable will rotate at a high speed to supply the bottle according to the requirements. The web wheel will clear the non-standard bottles. The bottle part supplied by the turntable will be fed into the processing part at a certain speed. The bottle-handling part is conveyed to the working surface of the conveyor through conveyor belts on both sides, and the bottle specifications are sorted out through different bottle-turners. The electronic control system monitors and feedbacks real-time through the sensors of each part to realize full-automatic operation, which is an indispensable machine for high-speed production, and saves a lot of manpower costs and avoids human factors. Losses.

Shanghai Special Bottling Machine Supplier

Performance characteristics:

AISI 304 stainless steel is used as the main material and can be modified as required.

Full Chinese touch screen, PLC control, automatic and efficient bottle management and bottle stoppage with production conditions;

Equipped with electrostatic precipitator, it can clean the inner part of plastic bottle; (optional)

It is suitable for plastic bottles of various shapes, such as round bottles, square bottles and special-shaped bottles. It is convenient to change product specifications. (We need to confirm)

Stainless steel support foot;

Large capacity stainless steel hopper, with no bottle alarm;

The acrylic cover of the hopper can be opened and closed automatically, which is convenient for workers to feed and dust-proof.

AISI 304 stainless steel case;

Engineering plastic conveyor belt, in line with GMP requirements.

Parameters:

Model

YP series

Zui high speed

250 bottles per minute

Suitable bottle body

20-60 mm or bottle width 20-60 mm

Suitable for bottle height

30 ~ 120mm

Power Supply

AC220V 50/60HZ

power

1.0KW

Shape Size (L X W X H)

2,550 mm x 1,200 mm x 1,430 mm

Air consumption

60L/min Clean Air

pressure

0.5 ~ 0.7Mpa

weight

About 600kg

Working principle:

The function of the special-shaped bottle arranging machine is to store the material manually into the storage bin. The material in the storage bin will be fed to the turntable at an automatic quantitative and set speed. The turntable will rotate at a high speed to supply the bottle according to the requirements. The web wheel will clear the non-standard bottles. The bottle part supplied by the turntable will be fed into the processing part at a certain speed. The bottle-handling part is conveyed to the working surface of the conveyor through conveyor belts on both sides, and the bottle specifications are sorted out through different bottle-turners. The electronic control system monitors and feedbacks real-time through the sensors of each part to realize full-automatic operation, which is an indispensable machine for high-speed production, and saves a lot of manpower costs and avoids human factors. Losses.

Shanghai Special Bottling Machine Supplier

Performance characteristics:

AISI 304 stainless steel is used as the main material and can be modified as required.

Full Chinese touch screen, PLC control, automatic and efficient bottle management and bottle stoppage with production conditions;

Equipped with electrostatic precipitator, it can clean the inner part of plastic bottle; (optional)

It is suitable for plastic bottles of various shapes, such as round bottles, square bottles and special-shaped bottles. It is convenient to change product specifications. (We need to confirm)

Stainless steel support foot;

Large capacity stainless steel hopper, with no bottle alarm;

The acrylic cover of the hopper can be opened and closed automatically, which is convenient for workers to feed and dust-proof.

AISI 304 stainless steel case;

Engineering plastic conveyor belt, in line with GMP requirements.

Parameters:

Model

YP series

Zui high speed

250 bottles per minute

Suitable bottle body

20-60 mm or bottle width 20-60 mm

Suitable for bottle height

30 ~ 120mm

Power Supply

AC220V 50/60HZ

power

1.0KW

Shape Size (L X W X H)

2,550 mm x 1,200 mm x 1,430 mm

Air consumption

60L/min Clean Air

pressure

0.5 ~ 0.7Mpa

weight

About 600kg