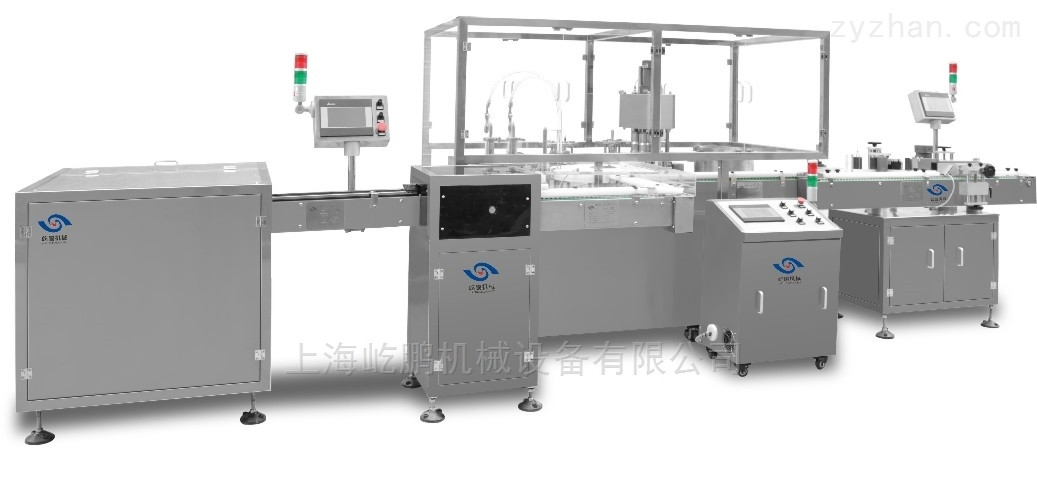

The top stopper mechanism of eyedrops filling machine structure: the first bottle moves intermittently to the stopper position through the turntable, and controls the work of the stopper turntable by the optical fiber detection to the control of the working signal of the stopper servo motor, so as to achieve the function of bottle stopper without stopper and bottle stopper. The second top stopper mechanism is designed by the principle of double arm manipulator, avoiding the use of springs or single arm manipulator for a long time before. Instability occurs. The whole process of the third stopper does not need air source and vacuum, and the stopper position has automatic positioning function. Therefore, the stopper is stable, pollution-free and accurate.

The capping mechanism of eyedrops filling machine structure: The first capping mechanism adopts constant torsion design, adjusts the torsion according to the tightness of the cap and the screw thread of the bottle mouth. When the cap is in place, it can automatically slip. The capping cover adopts imported silica gel material, so as to achieve the goal of not damaging the cap and not harming the bottle. The second bottle is positioned automatically by mechanical transmission, clamping, without pneumatic components, so the clamping bottle is stable, the surface of the bottle will not be injured and other functions.

Note: 1. It has the functions of no bottle without filling, no bottle without stopping and no stopper without capping.

2. The machine adopts unique top stopper mechanism and top cover mechanism, and the top stopper and top cover are accurate.

3. With emergency stop switch, automatic alarm when mechanical failure occurs. Equipped with remote control debugging device, it is convenient for equipment maintenance and use and debugging.

4. Submersible lifting filling does not drip or bubbles.

5. The filling needle is grinded smoothly with R60 degree chamfer without hanging liquid.

6. Rotary cap is used to balance the torque without damaging the cap.

7. The machine is equipped with laminar flow hood, which can eliminate noise (noise of the whole machine is less than 45 decibels).

8. Anti-acid and alkali corrosion (filling needle is polytetrafluoroethylene; infusion tube is imported silica gel tube; mesa coating is Teflon).

The capping mechanism of eyedrops filling machine structure: The first capping mechanism adopts constant torsion design, adjusts the torsion according to the tightness of the cap and the screw thread of the bottle mouth. When the cap is in place, it can automatically slip. The capping cover adopts imported silica gel material, so as to achieve the goal of not damaging the cap and not harming the bottle. The second bottle is positioned automatically by mechanical transmission, clamping, without pneumatic components, so the clamping bottle is stable, the surface of the bottle will not be injured and other functions.

Note: 1. It has the functions of no bottle without filling, no bottle without stopping and no stopper without capping.

2. The machine adopts unique top stopper mechanism and top cover mechanism, and the top stopper and top cover are accurate.

3. With emergency stop switch, automatic alarm when mechanical failure occurs. Equipped with remote control debugging device, it is convenient for equipment maintenance and use and debugging.

4. Submersible lifting filling does not drip or bubbles.

5. The filling needle is grinded smoothly with R60 degree chamfer without hanging liquid.

6. Rotary cap is used to balance the torque without damaging the cap.

7. The machine is equipped with laminar flow hood, which can eliminate noise (noise of the whole machine is less than 45 decibels).

8. Anti-acid and alkali corrosion (filling needle is polytetrafluoroethylene; infusion tube is imported silica gel tube; mesa coating is Teflon).