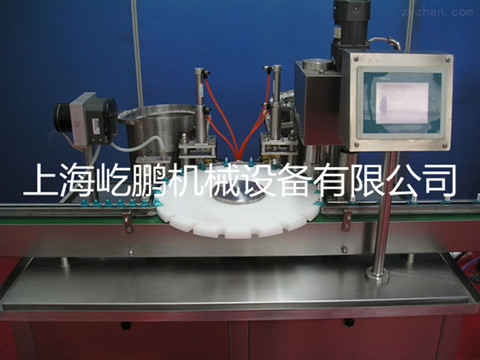

Scope of application of filling machine for diagnostic and therapeutic reagents

It is suitable for filling and capping of multi-specifications dosage packages such as biological reagents, immunomolecule reagents and clinical biochemical reagents. It absorbs the advantages and disadvantages of domestic and foreign counterparts and the actual feedback of customer production, and develops filling and capping equipment for batch production of diagnostic reagents. It is suitable for automatic filling of round, square and special-shaped bottles and automatic capping equipment of upper and outer caps. The machine has simple structure, stable performance and convenient maintenance.

Brief Introduction to the Products of Shanghai Medical Reagent Filling Machine

The machine has the advantages of accurate positioning, smooth transmission, accurate measurement and simplicity. Servo motor drives peristaltic pump filling, filling metering is accurate, filling does not drip and leak, with no bottle filling function; automatic top plug, outer cover, with no bottle, no bottle, no plug, outer cover function; PLC programmable control, touch screen man-machine interface system, simple and convenient operation; fully in line with GMP requirements.

Working principle

The bottle to be filled is first put into the oscillator of the automatic bottle handler. The bottle passes through the oscillator and is brought into the bottle turntable by the conveyor. The bottle enters the conveyor belt in sequence through the action of the bottle handler turntable.

The bottle detection sensor detects whether there is a bottle in the position, and the detection signal is sent to the internal control system to control the bottle filling and non-bottle filling.

If a bottle machine has been detected to start filling. Here is the second filling.

The bottle after filling enters the next level of the falling cover device through the working turntable.

Pre-screwing operation is performed on the bottle with the cap falling off.

The bottle with the cap pressed is put into the capping position for capping operation.

The finished product of Zui backswing cap is output by conveyor belt.

Product characteristics

This machine is intuitive and convenient to operate, no bottle filling, accurate measurement.

All electrical components adopt well-known brands.

U frequency conversion control, production speed arbitrary adjustment, automatic counting.

U is made according to GMP standard.

It is suitable for filling and capping of multi-specifications dosage packages such as biological reagents, immunomolecule reagents and clinical biochemical reagents. It absorbs the advantages and disadvantages of domestic and foreign counterparts and the actual feedback of customer production, and develops filling and capping equipment for batch production of diagnostic reagents. It is suitable for automatic filling of round, square and special-shaped bottles and automatic capping equipment of upper and outer caps. The machine has simple structure, stable performance and convenient maintenance.

Brief Introduction to the Products of Shanghai Medical Reagent Filling Machine

The machine has the advantages of accurate positioning, smooth transmission, accurate measurement and simplicity. Servo motor drives peristaltic pump filling, filling metering is accurate, filling does not drip and leak, with no bottle filling function; automatic top plug, outer cover, with no bottle, no bottle, no plug, outer cover function; PLC programmable control, touch screen man-machine interface system, simple and convenient operation; fully in line with GMP requirements.

Working principle

The bottle to be filled is first put into the oscillator of the automatic bottle handler. The bottle passes through the oscillator and is brought into the bottle turntable by the conveyor. The bottle enters the conveyor belt in sequence through the action of the bottle handler turntable.

The bottle detection sensor detects whether there is a bottle in the position, and the detection signal is sent to the internal control system to control the bottle filling and non-bottle filling.

If a bottle machine has been detected to start filling. Here is the second filling.

The bottle after filling enters the next level of the falling cover device through the working turntable.

Pre-screwing operation is performed on the bottle with the cap falling off.

The bottle with the cap pressed is put into the capping position for capping operation.

The finished product of Zui backswing cap is output by conveyor belt.

Product characteristics

This machine is intuitive and convenient to operate, no bottle filling, accurate measurement.

All electrical components adopt well-known brands.

U frequency conversion control, production speed arbitrary adjustment, automatic counting.

U is made according to GMP standard.